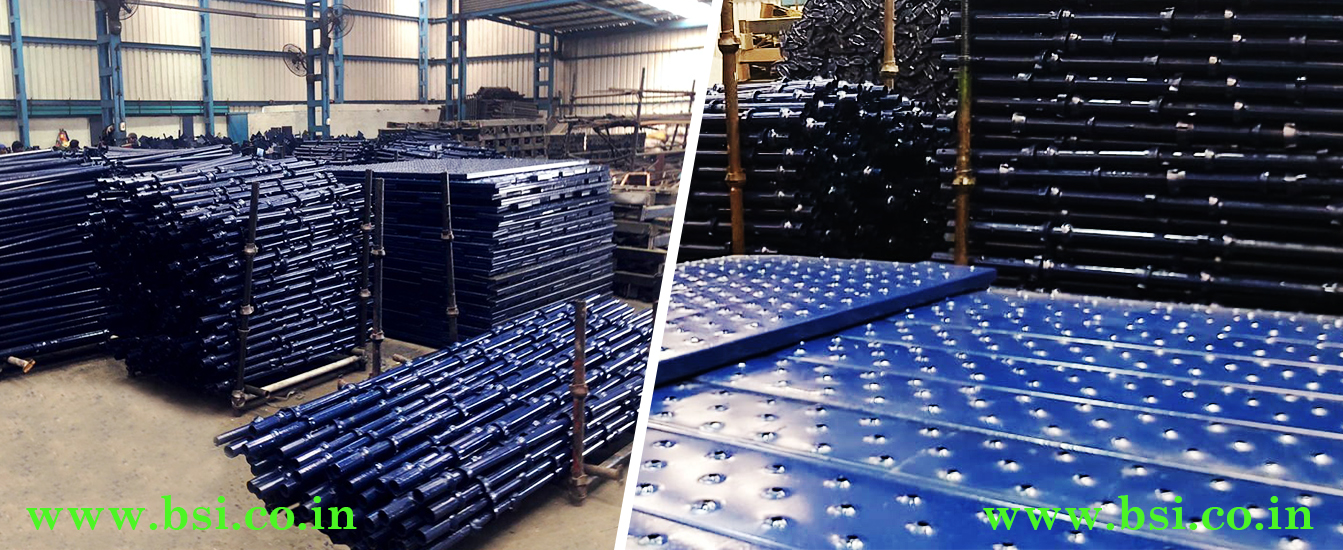

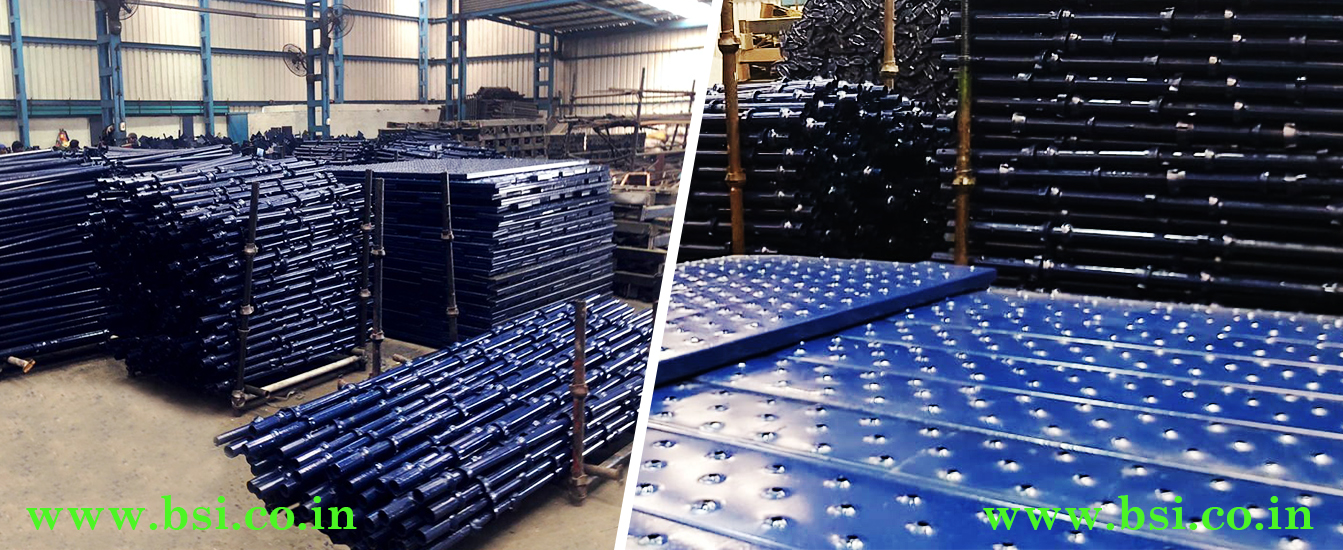

At Bishan Steel Industries, we are at the forefront of the Construction Industry as manufacturers of high-quality Aluminum Formwork Systems and Steel Scaffolding. With two sprawling, state-of-the-art factories located in Taloja, Mumbai, India, in close proximity to the sea port, we are strategically positioned to cater to the needs of construction projects nationwide.

Our commitment to innovation and cutting-edge technology is evident in our fully automated manufacturing facilities, equipped with advanced machinery and equipment. This ensures that our products meet the highest standards of quality, precision, and durability, enabling us to deliver superior formwork solutions to our valued clients.

With a strong focus on structural concrete formwork engineering and design, we provide comprehensive services for projects of all scales and complexities across WORLD. Our expertise encompasses a wide range of formwork solutions, including proprietary systems, custom-designed systems, and job-built systems. We specialize in the design and engineering of formwork for monolithic construction, stair cores, elevator cores, walls, one-sided walls, slabs, beams, girders, and various other structures.

Our highly skilled team of formwork DESIGNERS excels in handling complicated, state-of-the-art structures, extreme heights, and heavy loads. They collaborate closely with our clients' project teams, even during the bidding stage, to evaluate formwork solutions and devise effective planning strategies. With a focus on cost-effectiveness and safety, we strive to deliver concrete structures with impeccable quality finishes.

At Bishan Steel Industries we take great pride in our professionalism, timely project management, and unwavering dedication to customer satisfaction. We work closely with our clients to understand their unique requirements and deliver tailored formwork solutions that exceed their expectations.

Bishan Steel Industries experience the seamless integration of cutting-edge technology, expertise, and unrivaled customer service